Introduction and Overview

What is the FRAME Microscope?

The FRAME (Fast Rigid Automated Microscope Engine) represents a new approach to microscopy: an open, modular, automated, and flexibly adaptable microscope system. Based on UC2's (You.See.Too.) modular optics kit, the FRAME system lowers barriers to access complex optical and microscopy technology.

System Philosophy

Modular Design Principles

The FRAME system is built on complete modularization of all components regarding mechanics, electronics, and software:

- Interchangeable Modules: Cube modules can be freely exchanged to switch between brightfield, fluorescence, or interference microscopy

- Flexible Mechanics: Allows both, classical objective setups and free arrangements for special geometries

- Smart Electronics: Each cube can optionally have its own control unit for motors, galvo mirrors, or LEDs. All components share the same CAN BUS via 12V supply voltage.

- Open Interface: System control via user-friendly graphical interface or programming interface (Python, REST, CAN BUS, USB)

Key Innovation Areas

- Accessibility: Open-source hardware and software increase transparency, longevity, and interoperability

- Automation: Open system allows straightforward automation with built-in APIs for software control, camera integration, and laboratory automation

- Modularity: Instead of purchasing a completely new microscope, users can exchange or expand individual modules

- Cost Efficiency: Compared to proprietary complete systems, costs are reduced by 50-90% depending on configuration

System Overview

Mechanical Foundation

- Robust Aluminum Frame: Provides stable foundation for precise measurements

- Precision XYZ System: High-accuracy positioning and focusing mechanisms

- Removable Optics Unit: Modular design allows easy reconfiguration

- Slide-In System: Standardized 50mm cubes with quick-exchange capability

- Linear Objective Revolver: Switch between two different magnifications/resolutions

Electronic Architecture

- CAN-BUS System: Smart networking of all functional units

- Modular Controllers: ESP32 and Raspberry Pi-based control systems

- Remote Operation: Web-based interface with cloud connectivity

- IoT Integration: Network connectivity for remote monitoring and control

Software Ecosystem

The FRAME system integrates with several software platforms:

- ImSwitch: Advanced microscopy control software (http://github.com/openuc2/imswitch)

- UC2-REST: RESTful API for system control (https://github.com/openUC2/UC2-REST)

- UC2-ESP: Firmware for microcontroller-based modules (https://github.com/youseetoo/UC2-ESP32)

- Python Libraries: Extensive programming support for automation (e.g. https://github.com/openUC2/ImSwitchClient)

Applications and Use Cases

Research Applications

- Digital Pathology: Automated image acquisition with AI analysis for early cancer detection

- Cell Biology/Live Cell Imaging: Long-term observation of living cell cultures in incubators

- Laboratory Automation: Integration with pipetting robots in diagnostics and drug screening

- Advanced Microscopy: Super-resolution techniques, FLIM, and specialized imaging modes

Industrial Applications

- Quality Control: Materials inspection and defect analysis

- Biotechnology: Process monitoring and product validation

- Education: Modern imaging technique visualization in teaching and training

Advantages for Different User Groups

Research Institutions

- Flexibility: Adapt system to specific research needs

- Cost Efficiency: Lower initial investment and operational costs

- Scalability: Add capabilities as research evolves

- Community Support: Active user community and continuous development

Biotech Startups

- Low Entry Barrier: Affordable access to high-performance microscopy

- Rapid Prototyping: Quick iteration on experimental setups

- Modular Investment: Build system incrementally as funding allows

- Open Standards: Avoid vendor lock-in

Educational Institutions

- Teaching Tool: Demonstrate modern imaging techniques

- Student Projects: Hands-on experience with modular systems

- Budget Friendly: Accessible pricing for educational budgets

- Future Skills: Prepare students for open-source technologies

Sustainability and Environmental Impact

Resource Conservation

The modular approach contributes to sustainability on multiple levels:

- Repair & Maintenance: Instead of disposing of complete systems, only individual modules are replaced or adapted

- Upgrading: When components become outdated or new functions are needed, individual modules can be upgraded rather than replacing the entire system

- Local Production: Many mechanical components are produced locally via 3D printing using renewable materials

Open Source Benefits

- Global Accessibility: Electronic platforms can be replicated worldwide, including in resource-limited regions

- Knowledge Sharing: Open documentation promotes global access to high-end technology

- Community Development: Active community ensures continuous improvement and support

- Local Repairs: Using 3D printing and digital fabrication, broken parts can be repaired on site

System Configurations

Base Configuration

The basic FRAME system includes:

- Aluminum frame with XYZ positioning system

- Basic cube modules for brightfield microscopy

- Camera interface and basic illumination

- Control electronics and software

Advanced Configurations

Extended systems can include:

- Multiple illumination modes (fluorescence, polarization, DIC)

- Automated sample handling

- Multi-camera setups

- Environmental control (temperature, CO₂)

- Integration with laboratory automation systems

Getting Started

Before proceeding with installation and operation, ensure you have:

- Read all safety information in Section 1

- Verified system requirements detailed in Section 3

- Prepared installation space according to environmental specifications

- Organized necessary tools and accessories for assembly

The following sections will guide you through:

- Technical specifications and requirements

- Step-by-step installation procedures

- Comprehensive operation instructions

- Maintenance and troubleshooting guidance

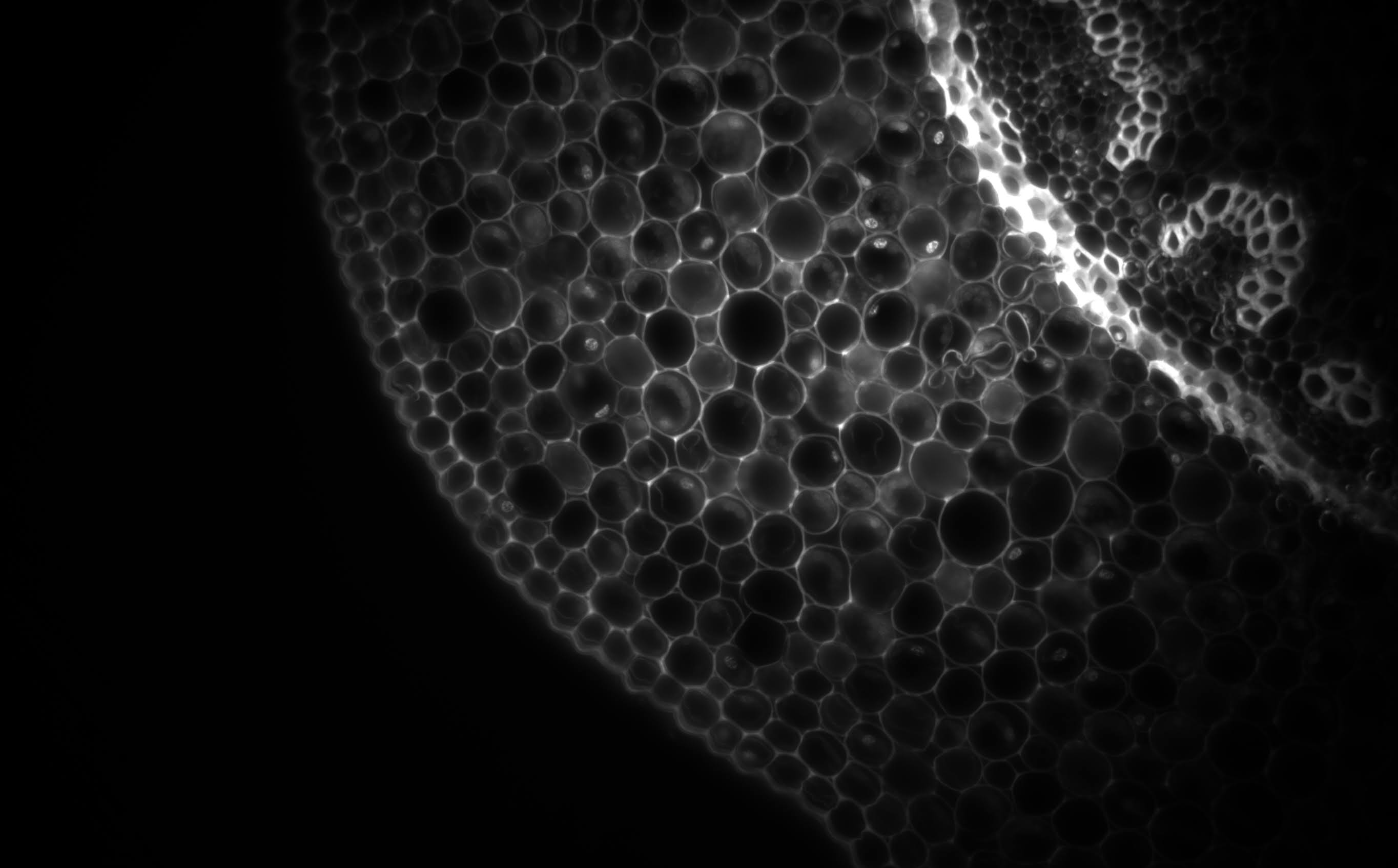

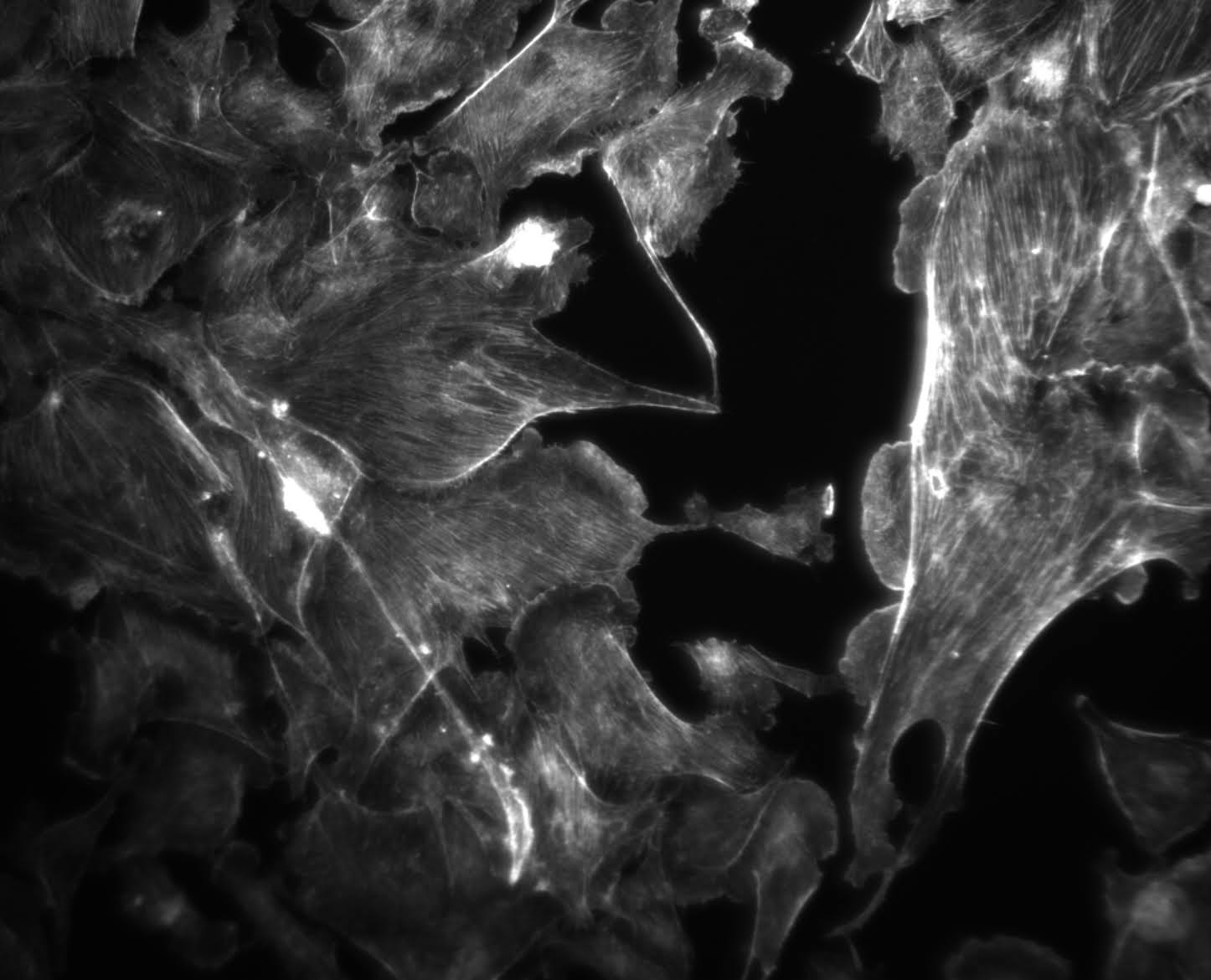

Results from the Fluorescence Channels

Continue to Technical Specifications for detailed system requirements and specifications.