GalvoIntro

mAIkroscope Galvo Interface Board – Extended Hardware & Firmware Documentation Rev A – 26 May 2025

1 Purpose & Key Features

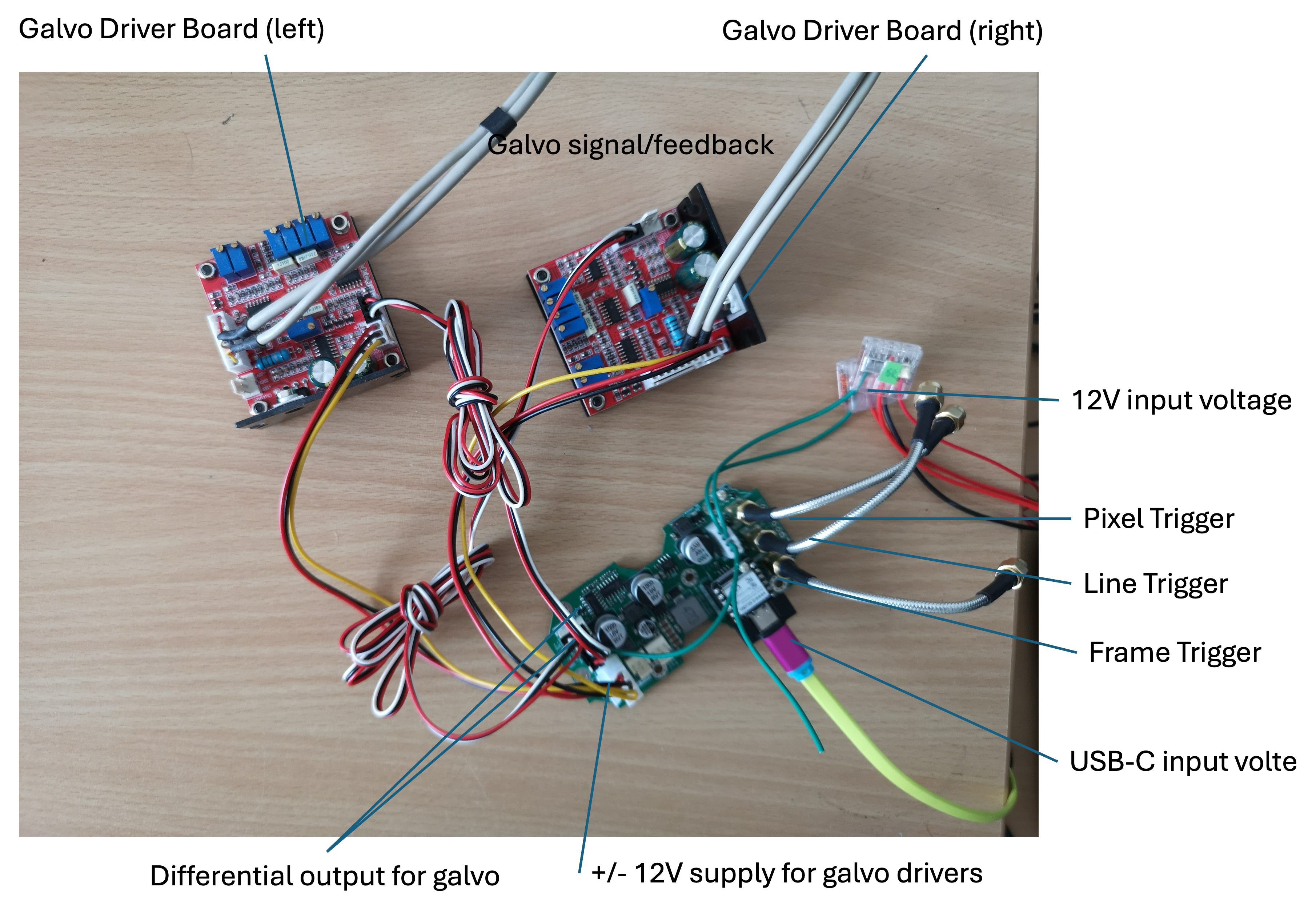

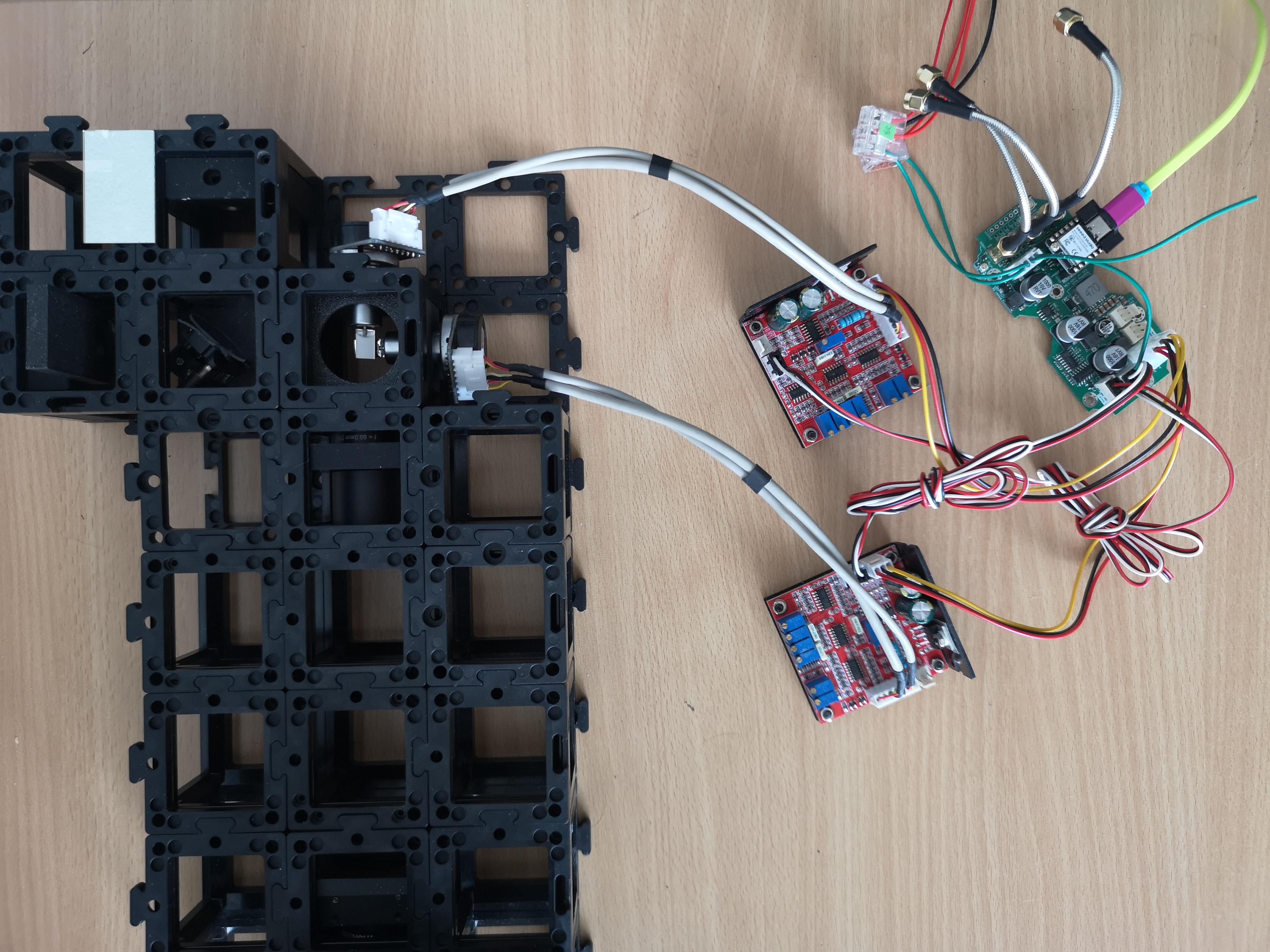

- Dual-axis galvo driver interface for UC2 microscopes.

- Seeed XIAO ESP32-S3 MCU handles scan synthesis and trigger generation.

- On-board 12-bit SPI DAC (MCP4822) creates ±10 V differential XY signals for low-cost Chinese galvo drivers.

- Three independent 50 Ω trigger outputs (pixel, line, frame).

- CAN 2.0B bus for remote control via UC2-CAN protocol.

- Integrated ±12 V/3.3 V/5 V analog rails, 2 A output budget for external driver modules.

This is a scan using the Flimlabs.com software, their detector and their pulsed lasers. This is a 512x512 pixel^2 area

2 System Architecture

ESP32-S3 ↔ SPI ↔ MCP4822 → LM324 diff amps → SMA L± / R±

│ │ ├─ pixel/line/frame triggers

│ │ └─ U.FL laser blanking

└─ TWAI CAN bus → SN65HVD230 → JST-XH backbone

- Two-phase DAC update: write 12-bit sample into DAC register (CS low), then pulse LDAC to latch both channels simultaneously; saves one SPI transaction per point.

3 Electrical Specifications

| Parameter | Value | Comment | | | - | -- | | - | | Backbone input | 12 V ±5 % | via J1001-1 | | | Board self-consumption | ≈ 50 mA | excludes external galvo drivers | | | Galvo supply pass-thru | ±12 V, 2 A max | J1004/J1007/J1008 | | | DAC resolution / range | 12 bit, 0 – 3.3V at 4096 steps | converted to ±10 V diff | | | Output bandwidth | ≈ 25 kHz (-3 dB) | limited by LM324 stage | | | Trigger level | 3.3 V CMOS, 50 Ω back-terminated | SMA J1009-J1011 | | | CAN bus | ISO11898-2, 1 Mbit/s default | 120 Ω terminator selectable (JP2001) | |

4 Connectors & Pinouts (summary)

- Power + CAN (J1001, JST-XH-4): GND, +12 V, CAN_H - CAN_L

- Galvo power out (J1004 big Molex 3.96 mm, J1007/J1008 KF2510): ±12 V, GND – pin order matches driver boards.

- Differential XY (J1005/J1006, SMA-3): L+, L-, GND and R+, R-, GND.

- Triggers (SMA-2): Pixel (J1009), Line (J1010), Frame (J1011).

- Laser blanking (J10001, U.FL): single-ended 50 Ω.

- XIAO headers (J1002/J1003): break out all ESP32-S3 I/O; see GPIO map in §7.

5 Analog Signal Chain

- MCP4822-E/SN generates 0-3.3 V (12-bit).

- Gain/offset network (LM324) maps 0 V→0 V, ±2.048 V→±10 V.

- Second LM324 stage inverts each leg, giving true differential L± and R±.

- Outputs drive ≥ 20 mA into the 10 kΩ inputs of typical galvo amps.

- LC filters on ±12 VA rails set 50 Hz cutoff to suppress switching noise.

6 Power Subsystem

- TPS5430 buck: 12 V → 3.3 V @ 0.8 A for MCU/CAN.

- TPS5430 inverting buck-boost: 12 V → −12 V @ 1.5 A for op-amps.

- 78L05 linear: 5 V A for DAC/reference.

- All rails filtered by π-LC networks; testpoints TP400x provided for bring-up.

7 Firmware Overview

// Default pin mapping (Arduino style) on XIAO systems

#define PIN_DAC_CS 8 // J1003-10 / GPIO8

#define PIN_DAC_SCK 7 // J1003-9 / GPIO7

#define PIN_DAC_SDI 9 // J1003-11 / GPIO9

#define PIN_DAC_LDAC 6 // J1002-6 / GPIO6

#define PIN_TRIG_PIXEL 2 // GPIO2

#define PIN_TRIG_LINE 3 // GPIO3

#define PIN_TRIG_FRAME 4 // GPIO4

#define PIN_CAN_TX 5 // GPIO5

#define PIN_CAN_RX 44 // GPIO44

#define PIN_LASER 43 // GPIO43

#define PIN_PUSHBUTTON 1 // GPIO1 (enable internal pull-up)

Loop structure:

for each Y line:

for each X pixel:

write X,Y to DAC; assert TRIG_PIXEL

assert TRIG_LINE

assert TRIG_FRAMECoordinate depth: 12 bit full-scale → map image size (e.g. 512 × 512) by

coord = (pixel * 4095) / (size-1).PlatformIO project: clone

openUC2/galvo-interface-fw, selectenv:xiao_esp32s3, build & upload via USB-C.UC2-CAN commands: Coming soon

8 Typical Operating Procedure

- Feed 12 V from microscope backbone into J1001-1 (CAN connecotr); connect CAN (optional), you can supply 12v/GND via the JST 4 Pin sconnector.

- Connect each galvo driver board with 3-pin power and SMA signal leads.

- Flash firmware; set parameters in firmware for min/max pixel and stepsize as well as pixel dwell time

- Monitor pixel trigger on oscilloscope

- Tune galvo PID on driver boards for minimal overshoot

9 iBOM

10 Firmware Architecture (openUC2-LaserScanner)

You can find the files here https://github.com/openUC2/openUC2-LaserScanner/blob/main/src/main.cpp

The UC2-ESP Firmware also has the CAN-enabled version of it in its code base here: https://github.com/youseetoo/uc2-esp32/blob/main/main/src/scanner/GalvoController.cpp

:::warn Sometimes the XIAO cannot be flashed immediately, for this you have to press boot and reset while firmware is flashed - or erase the firmware first using this tool: https://espressif.github.io/esptool-js/ :::

| Layer | Key files | Function |

|---|---|---|

| Application | src/main.cpp | Instantiates SPIRenderer, updates parameters in a while(1) loop, and calls start(); disables the watchdog and raises log level to warn for GPIO. (GitHub) |

| Render Engine | src/SPIRenderer.{h,cpp} | Converts image geometry into DAC samples, handles SPI transfers, and asserts pixel/line/frame triggers with single–cycle GPIO writes. Implements setParameters(), draw(), start(). (GitHub) |

| Board-select macros | same header | IS_XIAO, IS_XIAO_UC2GALVOBOARD choose the correct pin map at compile time. (GitHub) |

| Build system | platformio.ini | Two build environments: esp32dev (generic) and UC2_3_Xiao (Seeed XIAO ESP32-S3). Both use ESP-IDF with Arduino component; UART at 921 kbit s⁻¹. (GitHub) |

11.1 File structure

openUC2-LaserScanner

├── src/ # C++ sources

│ ├── main.cpp # app_main() entry point

│ ├── SPIRenderer.cpp # raster engine

│ └── SPIRenderer.h

├── include/ # (optional) extra headers

├── lib/ # third-party libs, e.g. UC2-CAN

├── python/ # helper scripts (ILDA, LUT generation)

├── KICAD/ # electrical design

├── platformio.ini # build targets

└── sdkconfig.* # pre-tuned IDF configs

11.2 Build flow (PlatformIO)

- Select UC2_3_Xiao in platformio.ini.

pio run→ ESP-IDF CMake → compile + link with Arduino component.pio run -t uploadflashes over USB-CDC (921 kbit s⁻¹).- Partition scheme

custom_partition_esp32s3.csvreserves PSRAM cache and 1 MiB for OTA.

11.3 Runtime tasks

| Task | Core affinity | Duty |

|---|---|---|

| mainTask (app_main) | core 0 | parameter sweep, calls renderer, yields 10 ms to scheduler. |

| IDF idle0/1 | core 0/1 | housekeeping (watchdog disabled for main). |

| Additional tasks (optional) | — | CAN listener, WebSocket, or CLI can be added; use xTaskCreatePinnedToCore. |

The code presently runs everything in the foreground; heavy processing (e.g. CAN command parsing) should be off-loaded to a FreeRTOS task to keep the raster loop deterministic.

11.4 SPIRenderer workflow

constructor()

├─ configure GPIO for laser, LDAC, triggers

├─ initialise SPI3 @20 MHz (XIAO) or HSPI (generic)

└─ pre-compute nX, nY from (X_MIN…X_MAX)/STEP

start()

└─ draw()

draw()

for each frame

assert all triggers high ← frame start

for X = X_MIN…X_MAX

for Y = Y_MIN…Y_MAX

clear triggers

hold LDAC low

SPI out 16-bit word to DAC-A (X)

SPI out 16-bit word to DAC-B (Y)

release LDAC ← both axes latch simultaneously

set pixel trigger, delay tPixelDwelltime µs

issue line trigger each X-loop

clear all triggers ← frame end

- Timing –

esp_rom_delay_us()delivers sub-µs waits; replace with a hardware timer ISR for dwell times <5 µs. - Throughput – one SPI transaction per axis, LDAC latched once per pixel → 2 × 16 bits @ 20 MHz ≈ 1.6 µs transfer; 512×512 raster ≈ 0.42 s per frame exclusive of galvo settling.

- Triggers – 50 Ω back-termination; rising edge marks start of integration for FLIM/PMT cards.

11.5 Customisation hooks

| Use case | Modification |

|---|---|

| Different image size | call setParameters() with new limits/step; renderer recomputes nX/nY without reallocating. |

| External control | add a CAN listener task that writes into a shared parameters struct guarded by a mutex; call renderer->start() from that task. |

| Scan patterns | replace the two nested for loops with a lookup table of (x,y) pairs (e.g. spiral, Lissajous). |

| Higher speed | use queued (spi_device_queue_trans) DMA transfers and toggle LDAC from SPI post-trans callback to overlap SPI and galvo settling. |

11.6 Pin map (compile-time)

| Signal | GPIO (UC2-Galvo) | GPIO (bare XIAO) |

|---|---|---|

| MOSI | 9 | 7 |

| SCK | 7 | 8 |

| CS | 8 | 9 |

| LDAC | 6 | 6 |

| TRIG PIXEL | 2 | 2 |

| TRIG LINE | 3 | 3 |

| TRIG FRAME | 4 | 4 |

| LASER blank | 43 | 43 |

Defined in SPIRenderer.h; switch boards via -DIS_XIAO_UC2GALVOBOARD or -DIS_XIAO build flag. (GitHub)

11.7 Extending the firmware

- Finite-state machine – wrap the renderer in a state class (IDLE, SCANNING, PAUSED).

- Streaming points – replace the nested loops by a ring buffer filled by CAN/UART for arbitrary point lists.

- Persistent settings – store last used scan parameters to NVS (

nvs_flash.h) and recall on boot. - Web OTA – enable

esp_https_otacomponent and reserve second app partition (already present incustom_partition_esp32s3.csv).