FocusLock

IR laser focus-lock module

Our microscope platform includes an optional focus-lock module that can be added to the FRAME at any time. The goal is to keep the sample in focus automatically during long experiments (e.g. STORM acquisitions, time-lapse imaging, incubator workflows) and to enable fast “return to focus” moves when scanning many XY positions (e.g. well plates).

Principle of operation

The below simulation from Ray-Optics shows the core idea:

Infrared laser injection

- A collimated infrared (IR) laser beam is routed into the microscope and aligned into the back focal plane (BFP) of the objective.

- Injecting the beam into the BFP ensures the beam exits the objective at a defined angle and probes the sample plane in a repeatable way.

Reflection at the coverslip

- At the sample, a small fraction of the IR light is reflected (typically at the coverslip/sample interface).

- The reflected beam travels back through the objective.

Separation and detection

- A dichroic / beamsplitter designed for IR separates the returning beam from the illumination path and directs it onto a dedicated monochrome camera (the “focus camera”).

Focus signal from spot motion

- As the sample moves along Z (focus direction), the detected spot position shifts on the focus camera (typically along X).

- This provides a continuous measurement that can be used as a feedback signal.

Two operating modes

1) Continuous focus lock (feedback mode)

- The system continuously measures the IR spot position and converts it into a focus error signal.

- This is most useful for long recordings where drift is expected (thermal drift, incubator drift, mechanical relaxation).

2) One-shot focus correction (positioning mode)

- The system measures the current focus offset once and performs a single Z correction.

- Typical use: multi-position experiments (well plates / mosaics), where each XY position gets an automatic focus adjustment before imaging.

Video demonstration

The following video shows the focus-lock in action during a long time-lapse experiment with deliberate temperature changes. The focus-lock keeps the sample in focus despite significant drift.

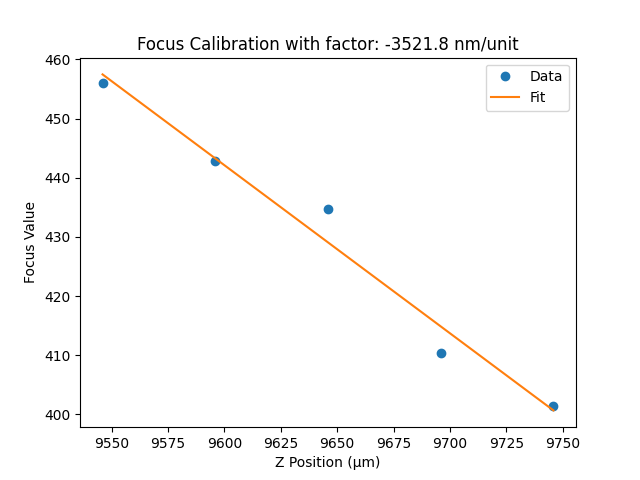

Calibration: spot position → defocus in µm

To convert “spot position” into an actual defocus value (µm), we run a short calibration:

- The system performs a controlled Z sweep over a defined range.

- For each Z position, the software measures the spot position on the focus camera.

- The result is a mapping curve (ideally close to linear over the working range).

- We fit a curve and accept the calibration only if the fit quality (e.g. R²) exceeds a threshold.

- Once calibrated, the focus-lock can report defocus in micrometer steps and apply accurate Z corrections.

Practical considerations and tuning

A few parameters strongly affect robustness:

- Camera exposure time: must be long enough for a clean signal, short enough for responsive feedback.

- Camera gain: should avoid saturation while keeping sufficient SNR for stable peak/spot detection.

- Peak/spot detection settings: tuned so the software reliably tracks the correct reflection spot.

The web interface exposes these settings and visualizes:

- Live focus camera images (optional polling)

- Continuous focus signal over time (time graph)

- One-shot correction triggers in the experiment view

Alignment and setup

For first-time setup or when switching objectives, the laser path may need adjustment.

- We provide a compact XY adjustment stage mechanically linked to the FRAME.

- This stage moves the focus-lock module in an intermediate plane so the IR beam is aligned to hit the objective’s BFP correctly.

- Best practice for calibration: use a reflective sample or a clean coverslip interface so the reflection spot is clear.

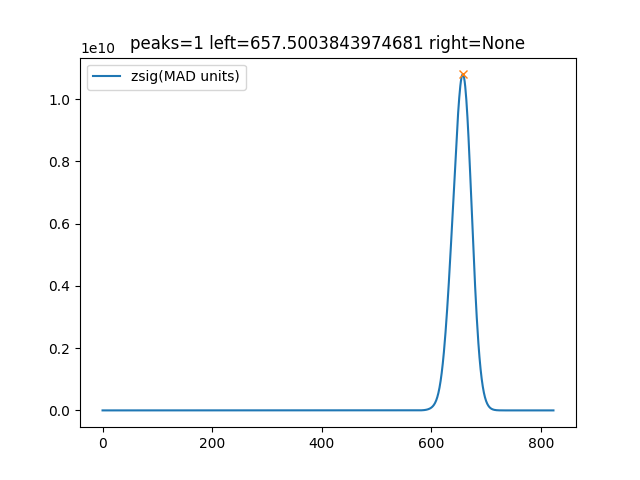

Two reflections (two spots)

Sometimes you may see two reflection spots, typically from the two coverslip surfaces.

- That’s normal.

- We aim to make the two spots well separated so the software can track the correct one reliably.

- Separation can often be improved by slightly shifting the module along the objective’s X direction (geometry dependent).

This image shows one distinct peak:

Hardware notes and roadmap

- Current implementation uses an IR laser (≈850 nm) and a monochrome camera integrated into the Raspberry Pi-based FRAME system.

- The focus camera is read automatically, and the focus value is computed in software.

- The module is designed to be compact and cost-effective, enabling advanced experiments even in constrained environments (e.g. incubators).

- We are currently in an extended testing phase before full release.

Long-term, we plan to offer different add-ons and variants optimized for different imaging channels and experimental needs.

Feedback welcome

This focus-lock module is actively evolving. If you test it in your workflows, we’d love to hear:

- which objectives you use

- the typical drift you see (per hour)

- your calibration quality and usable linear range

- edge cases (two spots, weak reflections, high background)