openUC2 Raspberry Pi HAT+ (FRAME Controller)

Technical specification, integration & bring-up guide

0) Quick links (hardware, firmware, docs)

- Schematics PDF (HAT+ Rev D): https://openuc2.github.io/kicad/hatplus-for-raspberrypi-5.pdf

- Schematics PDF (Panel Board): https://openuc2.github.io/kicad/hat-panelboard.pdf

- Firmware config reference (ESP32, HAT Master v2): https://github.com/youseetoo/uc2-esp32/blob/main/sdkconfig.UC2_3_CAN_HAT_Master_v2

1) Purpose & feature summary

- HAT+ for Raspberry Pi (40-pin header) providing:

- 12 V input -> on-board 5.1 V / 5 A buck for Pi, plus 3.3 V LDO for the ESP32-WROOM-32 and various sensors, E-Stop logic and interface chips.

- Safety chain with Emergency-STOP (3.5 mm TRS) gating the 12 V output to the backbone. Momentary "Buspower OFF" button for quick cut.

- CAN bus for distributed module control:

- Raspi: MCP2515 SPI controller + SN65HVD230 transceiver

- ESP32: Built-in CAN (TWAI) controller + SN65HVD230 transceiver

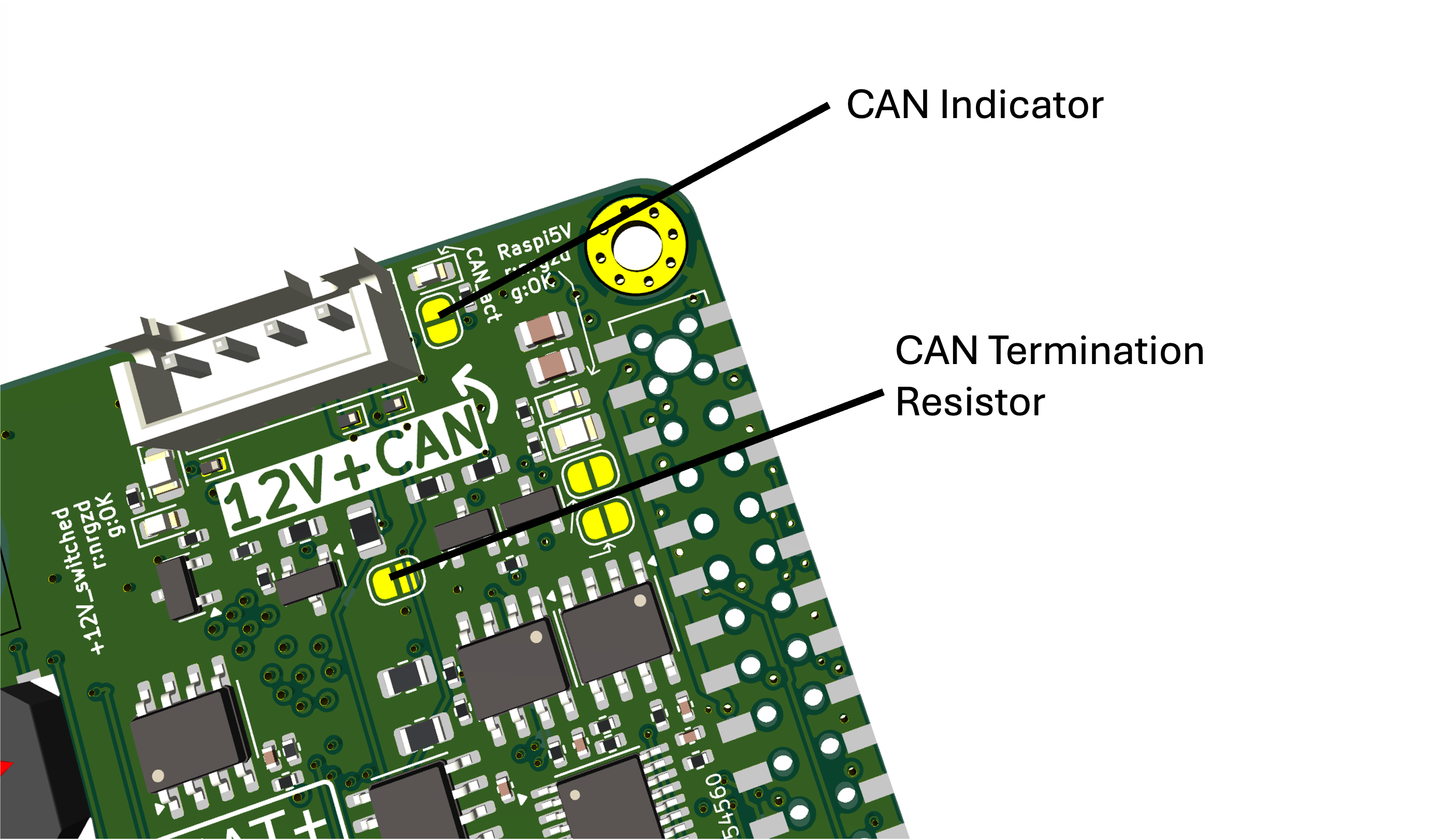

- Optional 120 ohm termination and CAN activity LED by solder jumpers.

- ESP32-WROOM-32E co-processor (USB-C + CP2102; also flashable via Pi UART with auto-program DTR/RTS).

- Sensors & I/O:

- INA226 current sensor (I2C addr 0x46)

- two TMP102 temperature sensors (I2C addrs typically 0x4A and 0x4B)

- NeoPixel header/extend, camera trigger out, fan tacho feedback, front-panel header

- Dual HAT+ EEPROMs (Standard class + Power MODE1 class "5 A capable") for automatic OS configuration. (not working currently, workaround through our Raspi OS)

2) Electrical architecture

2.1 Power path (12 V in -> 5 V / 3.3 V)

- Input: Barrel jack J101 (5.5 mm OD / 2.5 mm ID, center-positive), protected by a 7 A resettable fuse. Backfeed/ESD diodes protect rails and ports.

- Buck: TI TPS54560 set to about 5.1 V, rated for 5 A continuous (thermal-limited), with output network sized for step loads (design spreadsheet notes in schematic).

- LDO: AMS1117-3.3 (up to 1 A) generating 3.3 V for logic/sensors from the 5 V rail.

- Indicators & supervisors:

- 5 V present / OK window with MAX809 (2.93 V threshold in sensing chain) driving red/green LEDs (D401/D402). 5 V "OK" when above about 4.9 V.

- 3.3 V and switched 12 V likewise instrumented with LEDs/supervisors for fast bring-up diagnosis.

2.2 High-current "bus power" switching & safety

- Emergency-STOP chain (TRS jack J501): tip-ring must be normally closed externally; opening latches OFF.

- Sleeve supplies LED ground for the external box; power budget about 33 mA at 3.3 V.

- Main bus power switch: PMOS (Q602) producing

+12V_switched- Gate logic is driven by

BUSPOWER_ENand hard-gated by E-STOP and "buspower-off" lines. BUSPOWER_ENhas to be actively driven HIGH to turn on the big PMOS (see schematic note).

- Gate logic is driven by

- Bypasses (for troubleshooting only):

- JP601 "circumvent-buspower-switch": forces main PMOS ON (disables E-STOP, use only for lab debugging).

- JP201 "circumvent-power-software-switching": prevents Pi/ESP from cutting bus power via GPIO (safety-critical behavior may be altered).

3) Communication & control

3.1 Raspberry Pi interface (physical pin numbers)

- 3 (SDA1) / 5 (SCL1): I2C-1

- Solder jumpers JP101/JP102 can bridge Pi I2C to the board's shared I2C net (and to the ESP32 I2C if you close the bridge).

- 8 (GPIO14 TXD) / 10 (GPIO15 RXD): UART to ESP32 (paralleled with CP2102).

- 11 / 36: handshake lines used for ESP32 auto-program (via CP2102 wiring, see USB-UART sheet). Open JP901/JP902 to isolate if needed.

- 16 (GPIO23): buspower-off when HIGH (wired into the power gating logic).

- 19/21/23/24: SPI0 (MOSI/MISO/SCLK/CE0) to MCP2515.

- 32 (GPIO12): MCP2515 INT.

- 27/28 (GPIO0/GPIO1): I2C-0 for HAT+ EEPROMs (spec-reserved).

3.2 ESP32 pinout (Rev D / v2, used signals)

This is the pinout that matches the UC2_3_CAN_HAT_Master v2 definition and the Rev D schematic:

| ESP32 GPIO | Net / Function | Notes |

|:|||

| 21 | I2C-1 SDA | Shared sensor bus |

| 22 | I2C-1 SCL | Shared sensor bus |

| 17 | CAN RX (TWAI) | To ESP-side SN65HVD230 |

| 18 | CAN TX (TWAI) | To ESP-side SN65HVD230 |

| 19 | NeoPixel data | On-board WS2812 + neopixel-extend |

| 32 | Camera trigger out | Drives Panel Board camera trigger interface |

| 27 | Camera IO0 in | Reserved / optional |

| 33 | Camera IO2 IO | Reserved / optional |

| 4 | BUSPOWER_OFF (HIGH = off) | Software cut of +12V_switched |

| 34 | E-STOP sense (sense-emg-stop) | Input-only pin; HIGH = E-STOP asserted |

If you saw a PR in the

uc2-esp32repo that added this v2 pinout, this table is the consolidated version to keep here in the hardware README.

4) I2C pins (answer)

Raspberry Pi I2C (primary)

- Pi I2C-1 is on header pins:

- Pin 3: GPIO2 / SDA1

- Pin 5: GPIO3 / SCL1

ESP32 I2C (on the HAT)

- ESP32 uses:

- GPIO21 = SDA

- GPIO22 = SCL

Bridging Pi <-> ESP I2C

- JP101 (SDA) and JP102 (SCL) are the solder jumpers that connect the Pi I2C-1 lines into the HAT shared I2C net (and therefore to the ESP32 I2C pins and the I2C header ecosystem).

- Default should be OPEN unless you explicitly want the shared bus.

Practical note: the Pi has its own pullups on I2C-1. If the Pi is unpowered, the bus can behave oddly or backpower through pullups, so treat shared I2C with care when mixing power domains.

5) Temperature sensor (which one, pins, addresses)

- The HAT has two TMP102 temperature sensors on the shared I2C bus.

- Typical addresses on this design: 0x4A (ambient) and 0x4B (PCB temp), depending on ADDR strap.

- Pins:

- They sit on I2C-1 SDA/SCL (shared bus): ESP32 GPIO21/22 and optionally Pi pins 3/5 if bridged by JP101/JP102.

- ALERT:

- TMP102 supports ALERT, routed as open-drain in the design (board-level integration exists but may be left unpopulated or unused in firmware).

6) Buzzer (how it works)

- The buzzer is a 3.3 V driven beeper (BZ1501) switched by an NPN transistor (Q1501 SS8050).

- Signal is

buzzer-inputinto a base resistor network (R1501 5.6k, etc.). The transistor sinks current through the buzzer. - Recommended drive for loudest beep:

- 2.7 kHz, 50% duty cycle PWM.

- Arbitrary waveforms also work.

7) Emergency stop (how to detect)

Hardware behavior

- E-STOP is a TRS 3.5 mm jack (J501):

- Remote box uses an NC switch between Tip and Ring.

- Opening the loop triggers the safety chain and disables

+12V_switched(latched OFF by the gating logic).

- There is also an "override" (SW501 /

emg-stop_OVERRIDE) intended as a last-resort field bypass, protected against accidental use.

Firmware detection (ESP32)

- Read the E-STOP sense net on ESP32:

sense-emg-stopis wired to GPIO34 (input-only).- Logic on this board: HIGH = E-STOP asserted, LOW = operational (normal).

Pseudo-code:

pinMode(34, INPUT);

bool estop_hit = (digitalRead(34) == HIGH);

8) Switching off 12 V from ESP32 or Raspberry Pi (answer)

Yes: you can shut off the switched 12 V rail (+12V_switched) in two ways:

8.1 Software kill (fast, intended)

Two "buspower-off" lines are wired into the power gating logic:

- ESP32:

buspower-off_ESPon GPIO4 (HIGH = OFF) - Raspberry Pi:

buspower-off_raspion GPIO23 (Pi header pin 16; HIGH = OFF)

- ESP32:

This is a hard gate: if either line requests OFF, the switched 12 V is disabled.

8.2 Physical kill (local momentary)

- SW601 is a momentary "Buspower OFF" that forces OFF in hardware.

9) CAN activity and termination (which solder jumpers to bridge)

These are the useful field jumpers for CAN diagnostics and bus correctness:

JP801: enable on-board 120 ohm termination

- Bridge it only if this node is at one end of the CAN bus (one terminator per end).

JP802: enable CAN dominant-state indicator LED

- Helpful to visually confirm activity (adds a small load to the bus).

Other jumpers worth knowing:

- JP101 / JP102: bridge Pi I2C SDA/SCL into the shared I2C net (only if you want a shared bus).

- JP601 and JP201: bypass safety behavior (debug only, not for normal operation or shipping).

10) High current mode (reproducible activation, automated)

Goal: reliably allow high USB current draw on Raspberry Pi 5 (and avoid brownouts) by combining:

- correct power hardware (5.1 V / 5 A capability), and

- OS configuration that lifts the Pi USB current policy.

10.1 Current workaround (works today)

Add this to /boot/firmware/config.txt:

usb_max_current_enable=1

More information about that here: https://github.com/openUC2/rpi-imswitch-os/pull/48

This is OS-image controllable (automate it in your ImSwitch OS build / image pipeline).

10.2 Intended automated method (HAT+ EEPROM)

The design contains two HAT+ EEPROMs on Pi I2C-0 (GPIO0/1) to advertise the HAT class, including a Power MODE1 class ("5 A capable") so the Pi can lift power limits automatically.

Status: on early bring-up this is "not working currently" in the project notes, so keep the config.txt method in place until EEPROM programming + detection is validated end-to-end.

11) Firmware (ESP32 HAT Master v2)

Use this firmware config as the canonical reference for the v2 board:

Suggested repo structure for releases:

Provide prebuilt binaries for:

UC2_3_CAN_HAT_Master_v2.bin- plus

bootloader.binandpartitions.binif you are not using merged images

Link them from GitHub Releases and also from this README.

12) Panel Board (more information)

The Panel Board is a small front-panel / breakout PCB powered by the HAT and intended to:

Provide convenient connectors for:

- STEMMA / STEMMA QT I2C at 3.3 V

- 5 V addressable LED headers (ARGB-style)

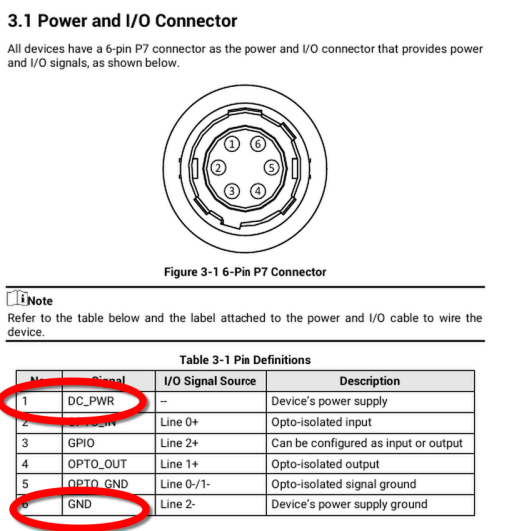

- SMA camera trigger output (for HIKROBOT camera Line 0)

- Fan header with tacho and controllable supply

12.1 Panel Board input connector from HAT (J101, 7-pin)

The harness from HAT to Panel Board carries:

I2C_SDAI2C_SCLneopixel(data)camera-trigger_esp-gpiofan_tachoGND+12V

The Panel Board generates its local 5 V and 3.3 V from the 12 V input.

12.2 STEMMA / STEMMA QT (I2C expansion)

Two connectors:

- JST-PH STEMMA (J107)

- JST-SH STEMMA QT (J106)

Output: 3.3 V + I2C, with max about 200 mA average (design note: 1 A peak), pullups are on the HAT (so do not duplicate aggressively).

12.3 5 V LED headers (ARGB / NeoPixel ecosystem)

LED headers provide:

- 5 V (up to 3 A from the local 12 -> 5 V buck on the Panel Board)

- NeoPixel data

- GND

There are multiple header styles to match common PC ARGB ecosystems (notes in schematic).

12.4 Camera trigger output to HIKROBOT (SMA)

The Panel Board includes a level interface that takes the ESP32 3.3 V trigger (

trigger_from-ESP) and drives a 12 V level suitable for the camera input (HIKROBOT Cam In Line 0).Implementation:

- NPN transistor + PMOS high-side stage (AO3401A) to drive the camera optoisolator input correctly.

Important notes from the schematic:

- Camera input is effectively an optocoupler LED with an internal resistor and needs a minimum voltage.

- This board drives a "12 V signal level" to meet the camera input requirements.

12.5 Fan header and controllable fan supply

The Panel Board provides a 3-pin fan connector (J401) with:

- GND

Tacho(open-drain from fan)- a controllable supply rail (

DCDC_FAN_VOUT)

Fan supply generation:

- A buck converter stage that can produce a variable output (design notes indicate 12 V down to about 3 V).

- Control uses an I2C digital potentiometer MCP4017 at I2C address 0x2F (design note).

- There is a local 3.3 V LDO supply dedicated for the fan control subsystem.

13) Linux integration (CAN & sensors)

13.1 MCP2515 overlay (Pi-side CAN on Linux)

- SPI0 CE0 (CS), INT at GPIO12, SCK/MOSI/MISO on pins 23/19/21.

- Example

/boot/firmware/config.txt:

dtparam=spi=on

dtoverlay=mcp2515,spi0-0,interrupt=12,oscillator=16000000

Then:

sudo ip link set can0 up type can bitrate 500000

candump can0

13.2 Sensors (I2C)

sudo apt install i2c-tools

i2cdetect -y 1

Expected addresses:

- INA226: 0x46

- TMP102: typically 0x4A and 0x4B

14) Field solder-jumpers quick table

| Jumper | Action |

|---|---|

| JP801 | Add 120 ohm CAN termination |

| JP802 | Enable CAN dominant-state LED |

| JP101 | Bridge Pi I2C SDA into shared I2C net |

| JP102 | Bridge Pi I2C SCL into shared I2C net |

| JP601 | Force bus power ON (bypass E-STOP) |

| JP201 | Disable Pi/ESP software power-off |

| JP901/JP902 | Open to isolate Pi from CP2102 RTS/DTR |

15) Appendix: default pin maps

15.1 Default Raspberry Pi header map (summary)

| Pin | Function | | -: | | | 3 / 5 | I2C-1 SDA/SCL (bridgeable via JP101/JP102) | | 8 / 10 | UART TX/RX to ESP (paralleled with CP2102) | | 16 | buspower-off (HIGH = off) | | 19/21/23/24 | SPI0 MOSI/MISO/SCLK/CS0 -> MCP2515 | | 32 | MCP2515 INT (GPIO12) | | 27 / 28 | I2C-0 SCL/SDA -> HAT+ EEPROMs |

15.2 ESP32 used pins (summary)

| GPIO | Function | | : | | | 21 / 22 | I2C SDA/SCL | | 17 / 18 | CAN RX/TX (TWAI) | | 19 | NeoPixel | | 4 | BUSPOWER_OFF (HIGH = off) | | 34 | E-STOP sense (HIGH = asserted) | | 32 | Camera trigger out | | 27 / 33 | Camera IO (reserved) |

15.3 Trigger Layout for HIK CAmera

The colour code is: camera in opto pin 2 => yellow, camera gnd opto pin 5 => white. It's soldered to the SMA connector. Can you please document that in the HATv2 More info openUC2/TechnicalDocs-openUC2-FRAME#134